A significant quantity of the world’s natural gas is ‘flared,’ or burned off, due to prohibitive transportation and processing costs that make it uneconomical in a gaseous state. This gas (‘stranded gas’) typically exists as associated gas at oil wells, where transportation of liquid petroleum to market is economical, though that of gas is not. As a result, it is flared and therefore wasted. One way to eliminate this waste is to perform gas to liquid (GTL) conversion at the source. Since the natural gas source is relatively small, the conversion requires compact GTL plants. An analysis has been performed and shows that methanol produced in this way can be competitive with conventional methanol and dimethyl ether (DME) production. This system techno-economic and market analysis of small-scale methanol production was done using syngas that is produced in an internal combustion engine (‘engine reformer’), using methane from a stranded gas source.

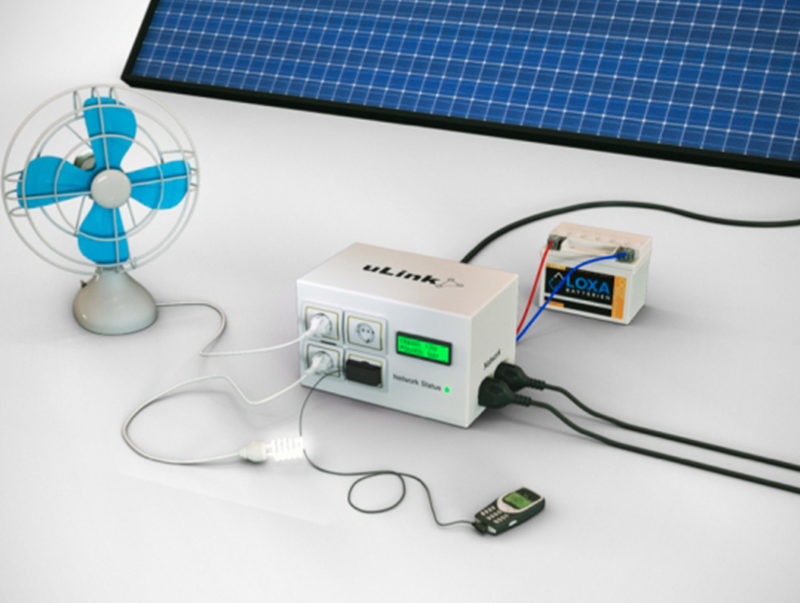

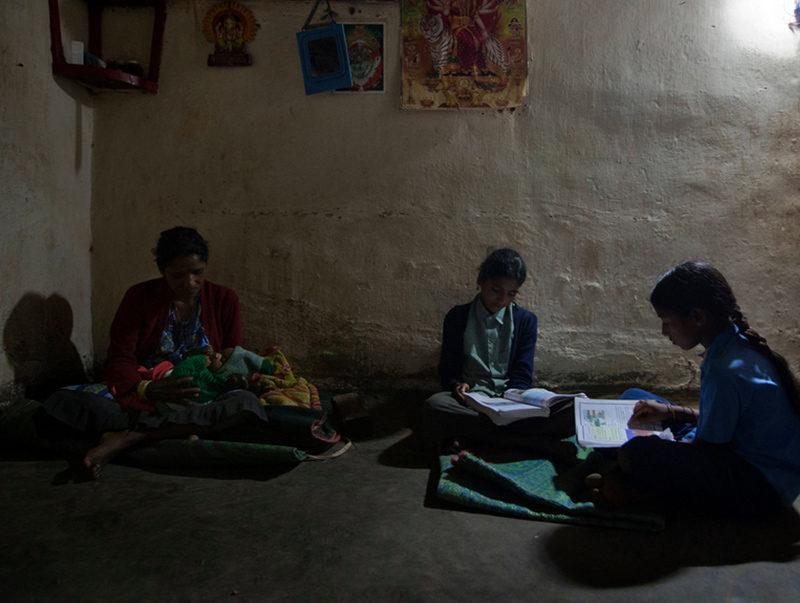

These fuels can be used as clean-burning, low-cost replacements to diesel and CNG for transportation applications, and LPG and kerosene in domestic applications. While these fuels (with the exception of diesel) are considered clean-burning as well, they must be imported and subsidized by the government. With a compact system, which can utilize otherwise wasted methane sources, developing countries can produce replacement fuels domestically, improving their energy security.

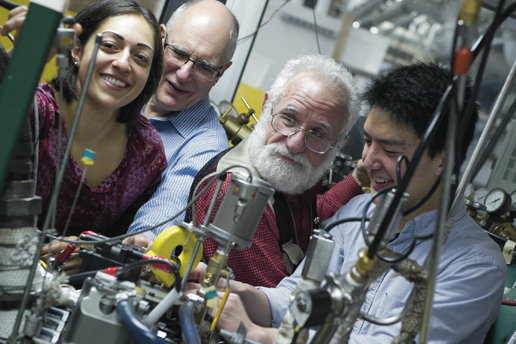

This work includes a new GTL technology that promises significantly more favorable cost-scaling. In particular, focus is on an experimental apparatus to characterize a novel reformer technology based on internal combustion engines. The system developed investigates partial oxidation of rich methane mixtures.

A diesel engine is selected for its robust construction and tolerance of high peak cylinder pressure and pressure rise rates. The engine is adapted for spark-ignition operation and thoroughly instrumented.

The system is currently in scale-up stage, with a demonstration plant being set up at the Research Triangle Park in North Carolina.

Project Media:

Paper: Small-Scale Natural Gas to Liquid Fuels Conversion Using Internal Combustion Engines